Sunny Lee

Character

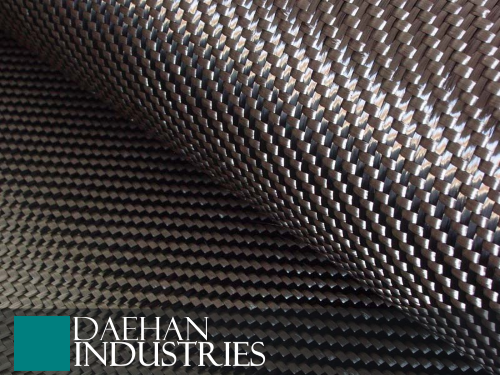

Image Source: http://pt.made-in-china.com/co_huatian888/product_Carbon-Fiber-Kevlar-Hybrid-Fabric_hrgsggrgy.html (edits by me)Intent: To create a base textile that may be used in future products and submissions.

Development Thread: If needed

Manufacturer: Daehan Industries

Model: ARA 202

Affiliation: Closed Market

Modularity: Available in different grades/weights

Production: Mass-produced

Material: Polymers, quantum fiber, chemical compounds

Strengths:

· Versatile: may be used to a variety of purposes

· Can be used as a standalone product or as a composite material

· High protective qualities (anti-blaster, ballistic defense, cut and abrasion protection)

· Heat and corrosion resistant

Weaknesses:

· Low compressive strength

· Very limited protection against lightsabers (glancing blow)

· Long exposure to UV will cause fiber degradation over time

Description:

Developed by the Daehan textile research laboratory in Sejong, Seoul, Protera is a very strong blend of polymers, specifically engineered to be flexible, light, and protective. The formula developed by Daehan Industries boasts a superior internal strength due to the way the molecules have been arranged, and is enhanced when the fibers are tightly woven. Protera is made in two main phases, and it began with the creation of a special blend of synthetic polymers. At completion, this raw material takes on the appearance similar to that of plastic pellets. In addition to the proprietary blend of polymers, quantum fiber was also added for additional protective properties. Once the polymer material has been created, it is dissolved in a chemical compound, and then extruded through a spinneret to form a filament fiber via a process called wet spinning.

The Protera fibers can be tightly woven together to create a textile, or even cut and mixed with other fibers (cotton, other synthetic blends). However, if added to another fiber mix, protective properties will be less. In addition to filament yarns, the fiber may take the form of pulp, spun-lace and paper-like sheets. The fiber was engineered to absorb and disperse energy attacks, and the stiff structure of the woven guards against abrasion, cuts, and projectiles. The plastic fiber is also inherently flame resistant, has a high chemical resistance, and low electrical conductivity. As such, Protera is often used to create protective vests and light armor. The textile can be used alone, sewn as an interlining, or applied in layers as a composite material. Despite the stiffness of the fabric, it is still quite flexible and very lightweight, making it an ideal material for use in armors -- it is most effective when multiple layers are used.

During extensive product testing at Daehan labs, it was discovered that Protera was highly durable. However, all materials have their limits. Blaster bolts at close range were dispersed with minimal molecular slippage, but multiple attacks to the same area caused fabric deformation. This greatly reduces the overall effectiveness, and may loosen the weave enough for subsequent attacks to break through. Similarly, repeated cuts or damage from projectiles weakens the textile and may eventually cause fiber breakage and product failure.

In addition to armor, Protera can be used in simple consumer goods or various other industrial processes - ropes, cables, cords, footwear, cut resistant gloves, ship components.

Primary Source: N/A

Affiliation changed from Open Market to Closed Market