Gray Raxis

Blind and Broken

Intent: Highly resilient, light weight material for the use in products and selling

Development Thread: N/A unless required

Manufacturer: Raxis Independent Designs

Model: N/A

Affiliation: RID

Modularity: Limited- color

Production: Major production

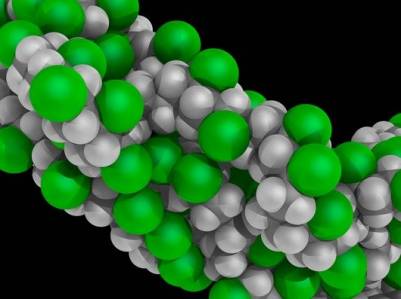

Material: Synthetic material created by using carbon and silicon as a base

Strengths:

Resistant- Silicar is highly resistant. It is able to resist high levels of both heat and cold before becoming brittle. It is able to resist high levels of electricity. It is highly resistant to both acids and bases, so only the most corrosive of either is able to effect the polymer. This resistance means it is able to handle environmental events such as acid rain or electrical storms that may arise suddenly. The material can withstand 6-8 hours of such events before it begins to suffer negative effects depending on the intensity of the event.

Strong Bonds- Silicar is a material that has strong molecular bonds. This means that it is able to withstand high levels of continuous strain and sudden impact. The material is able to do this due to the bonds giving it the ability to spread the shock of impact or strain across the material evenly. This means that the more surface area being exposed to impact at once, the more it is able to spread out and withstand.

Weaknesses:

Focused Impact- Silicar has difficulty being able to withstand impact that is focused on small areas. Because it spreads the shock of impact evenly across the material, the less surface area that is directly being exposed to the shock of impact the harder it is for the material to spread it out. This means that weapons designed to pierce defenses by minimizing the area of impact, such as most slug throwers and blasters, can easily break through the material.

Repairs- Silicar is difficult to repair. This is due to the fact that the material spread out as much stress across the material as it can. Because it spread out stress, when part of the material breaks it also means that a larger area than the area of impact/strain becomes broken or severely weakened as well. This fact makes it so that it is far easier to just replace any damaged silicar than to try to repair it, because it becomes nearly worthless after.

Description: Raxis Independent Technology has a little different philosophy from most other companies when it comes to personal protection equipment, and so they knew they would need a new material that was just as different. The task of creating this new material was left up to a group of scientists and they soon began to look into materials, both natural and synthetic, that already existed. They looked into everything from polymers to ceramics to carbon fiber to even different types of quartz. The research proved to be both fruitful and unproductive at the same time. They found many materials that met some of the properties they wanted and even a few that met many of them, but they could not find one that met all of them.

After some time an idea eventually was formed for a new material. This idea was inspired in part to silcon carbide. The naturally occurring mineral possessed great potential, so what if they combined it with processes involved in creating polymers? They used this concept and began to experiment with combining silicon and carbon together in the lab while slowly adding different and varying amounts of other elements to the mixture. The trial and error continued for some time until the prototype for silicar eventually was developed. This prototype was nearly a perfect fit for the qualities they wished from the material they were needing to create.

The scientists had one issue they needed to fix with the prototype to get it exactly how they wanted it. The prototype was conductive to electricity which meant any equipment made out of it would not protect from electricity. They began to make several adjustments to it until the final incarnation of silicar was created. They were able to switch the semi-conductive nature of the material thanks to the silicon half of its base to that of being an insulator. With this silicar as finally finished being developed and as a bonus to they also learned how to adjust the color without effecting the effectiveness of the material.

Extensive testing of the newly developed material, as per RID policy, was undertaken to get accurate readings on the properties. It was quickly discovered that the material could handle high levels of most forms of environmental effects as well as high levels of stress and impact the more surface area that was effected. This proved to be very promising for industrial needs as well as for exploration. Testing was soon done to see the material's potential for weaponization. It quickly became clear that the properties that made the material work so well for non-combat purposes were detrimental to its use for combat purposes. It was not able to withstand shots from many different types of guns, and as an added problem it proved to be very difficult to repair. With testing finished, the product was presented to Gray for finally approval.

Silicar ended up being a unique material that sits between being a crystal such as quartz and a polymer such as plastic. Because of this, it looks a plastic at first glance but upon close inspection begins to look more like a crystal. This also means that the material can be very bright and reflect light if colored a more light color. While this can be annoying to some it can also appeal to others. This odd property however does not add any practical use. The material can not be used for the same kind of uses for light as quartz or other crystals might.

Primary Source: N/A